Polyurethane Blades: A Smart Choice for Efficient Processes

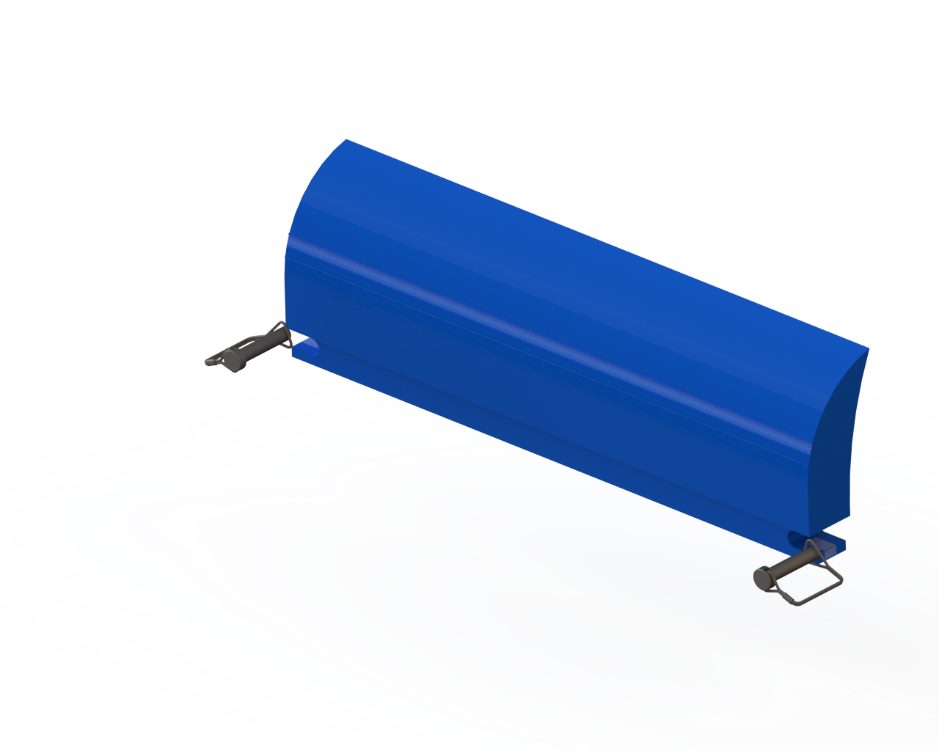

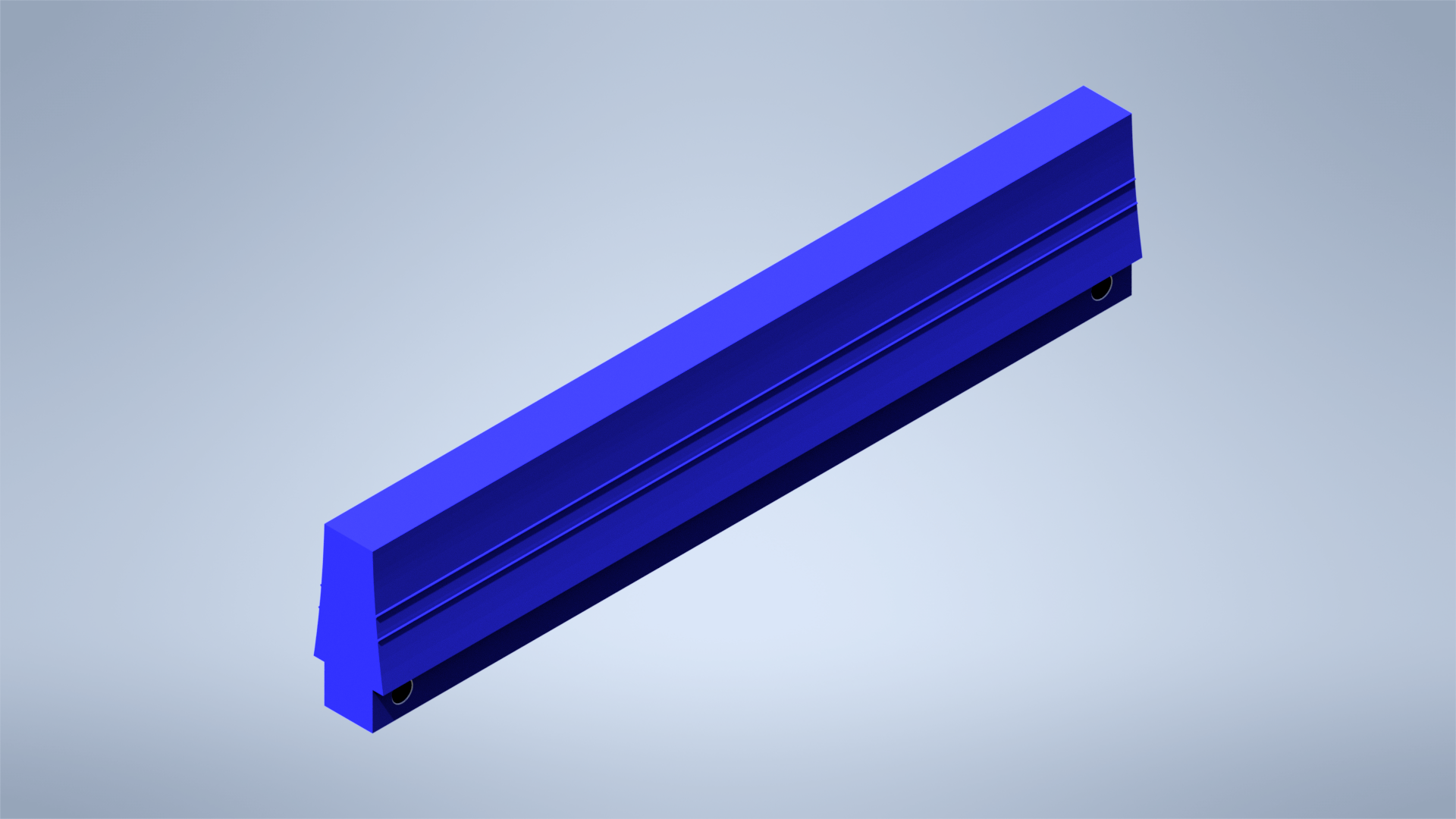

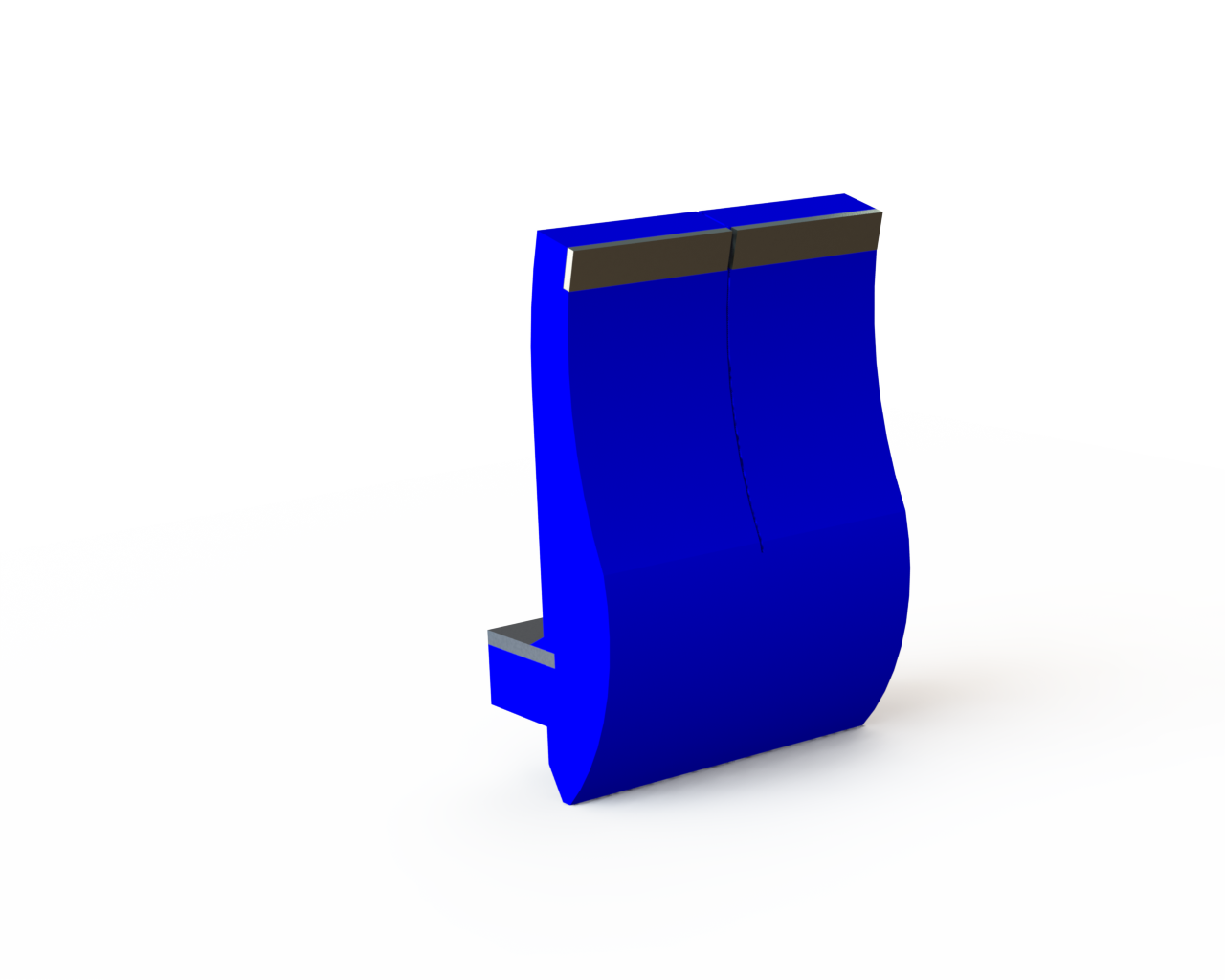

Polyurethane blades are widely used in industrial cleaner systems due to their combination of flexibility, strength and durability. Manufactured with high-performance material, polyurethane blades effectively remove residues from conveyor belts without damaging surfaces.

These blades are particularly advantageous in sectors handling light and moderately abrasive materials, such as agribusiness, food industry and recycling. Besides offering high wear resistance, polyurethane blades are lighter, facilitating installation and system maintenance.

Another important benefit is resistance to chemicals, oils and weathering, making polyurethane blades versatile for different industrial environments. With excellent cost-benefit, they contribute to improved operational efficiency and reduced maintenance costs.

6 Advantages of Using Polyurethane Blades

Polyurethane blades offer several advantages when used in industrial cleaner systems. These benefits make them a popular choice in sectors requiring high performance and durability. See the main advantages of polyurethane blades:

- Maintaining belt cleanliness: The primary cleaner removes material residues adhered to the belt immediately after the discharge point, preventing accumulation that could cause system failures and unplanned stops.

- Extended belt lifespan: By preventing wear caused by retained particles, the primary cleaner reduces damage to belt surfaces and conveyor components.

- Reduced operational costs: With decreased corrective maintenance needs and optimized material transport, operational costs are significantly reduced.

- Improved safety: Eliminating material accumulation along the conveyor creates a safer environment, reducing accident risks.

- Greater productivity: With a clean and efficient transport system, production becomes continuous and uninterrupted, increasing operational productivity.

- 6. Easy installation and replacement: Polyurethane blades are lighter and easier to handle, facilitating quick installation and replacement, minimizing downtime.

These advantages make polyurethane blades an efficient, economical and sustainable solution for industrial transport systems, especially in processes requiring high performance and resistance.

Polyurethane Blades vs Steel Blades

- Polyurethane Blades: Flexible, wear-resistant and more suitable for light materials like grains and food products. They generate less noise, require less maintenance and have lower initial cost. However, they have shorter lifespan in heavy and abrasive material environments.

- Steel Blades: More durable and wear-resistant, ideal for heavy and abrasive materials like ores. Although more expensive initially, they offer greater resistance in extreme conditions and require fewer replacements, despite generating more noise and vibration.

The choice between them depends on the transported material type, operating conditions and involved costs.

Buy Polyurethane Blades at Rasper Equipment

Rasper is an engineering company specialized in providing high-quality equipment and services for the industrial sector. Located in Arujá - SP, Rasper stands out for manufacturing and commercializing belt conveyor parts and accessories, along with complete maintenance services.

With an innovative vision and commitment to excellence, Rasper serves clients throughout Latin America and Europe, delivering solutions that optimize industrial processes and ensure high efficiency. Its products are developed with advanced technology and strict quality standards, meeting demands from various industry segments.

Over the years, Rasper has established itself as a reliable partner, providing specialized technical support and customized solutions. Whether in system modernization or equipment maintenance, Rasper is a reference for services that promote productivity, safety and durability in industrial environments.